Il existe une déconnexion fondamentale entre la richesse des données numériques dont nous disposons et le monde physique dans lequel nous les appliquons. Alors que la réalité est tridimensionnelle, les riches données dont nous disposons aujourd’hui pour éclairer nos décisions et nos actions restent piégées sur des pages et des écrans bidimensionnels. Ce fossé entre le monde réel et le monde numérique limite notre capacité à tirer parti du torrent d’informations et de connaissances produites par des milliards de produits intelligents et connectés dans le monde.

La réalité augmentée, un ensemble de technologies qui superposent des données et des images numériques sur le monde physique, promet de combler ce fossé et de libérer des capacités inexploitées et uniquement humaines. Bien qu’elle n’en soit qu’à ses débuts, la réalité augmentée est sur le point de devenir un phénomène courant ; selon une estimation, les dépenses consacrées à la technologie de la réalité augmentée atteindront 60 milliards de dollars en 2021. La RA touchera les entreprises de tous les secteurs et de nombreux autres types d’organisations, des universités aux entreprises sociales. Dans les mois et années à venir, elle transformera notre façon d’apprendre, de prendre des décisions et d’interagir avec le monde physique. Elle changera également la façon dont les entreprises servent leurs clients, forment leurs employés, conçoivent et créent des produits, gèrent leurs chaînes de valeur et, en fin de compte, la façon dont elles sont compétitives.

Dans cet article, nous décrivons ce qu’est la RA, l’évolution de sa technologie et de ses applications, et pourquoi elle est si importante. Son importance va croître de manière exponentielle avec la prolifération de la consommation de produits connectés, car elle amplifie leur pouvoir de créer de la valeur et de remodeler la concurrence. La RA deviendra la nouvelle interface entre les humains et les machines, faisant le lien entre les mondes numérique et physique. Bien qu’il reste des défis à relever pour la déployer, des organisations pionnières, telles qu’Amazon, Facebook, General Electric et l’U.S. Navy aux Etats Unis, et des entreprises françaises comme Renault, Naval Groupe, Airbus, Monoprix, Alstom ou PSA mettent déjà en œuvre la RA et constatent un impact majeur sur la qualité et la productivité. Nous fournissons ici une feuille de route sur la manière dont les entreprises devraient déployer la RA et expliquons les choix critiques auxquels elles seront confrontées pour l’intégrer dans leur stratégie et leurs opérations.

Des applications isolées de la RA existent depuis des décennies, mais ce n’est que récemment que les technologies nécessaires à l’exploitation de son potentiel sont devenues disponibles. À la base, la RA transforme des volumes de données et d’analyses en images ou en animations qui sont superposées au monde réel. Aujourd’hui, la plupart des applications de RA sont diffusées par des appareils mobiles, mais de plus en plus, la diffusion se fera par le biais de dispositifs portables mains libres, tels que des écrans montés sur la tête ou des lunettes intelligentes. Bien que de nombreuses personnes soient familiarisées avec les applications de RA simples et divertissantes, telles que les filtres Snapchat et le jeu Pokémon Go, la RA est appliquée de manière beaucoup plus conséquente dans des environnements grand public et professionnels. Par exemple, les affichages “tête haute” de la RA qui placent la navigation, les avertissements de collision et d’autres informations directement dans le champ de vision des conducteurs sont désormais disponibles dans des dizaines de modèles de voitures. Des dispositifs de RA portables destinés aux ouvriers d’usine, qui superposent les instructions de production, d’assemblage ou de service, sont testés dans des milliers d’entreprises. La RA complète ou remplace les manuels et les méthodes de formation traditionnels à un rythme toujours plus rapide.

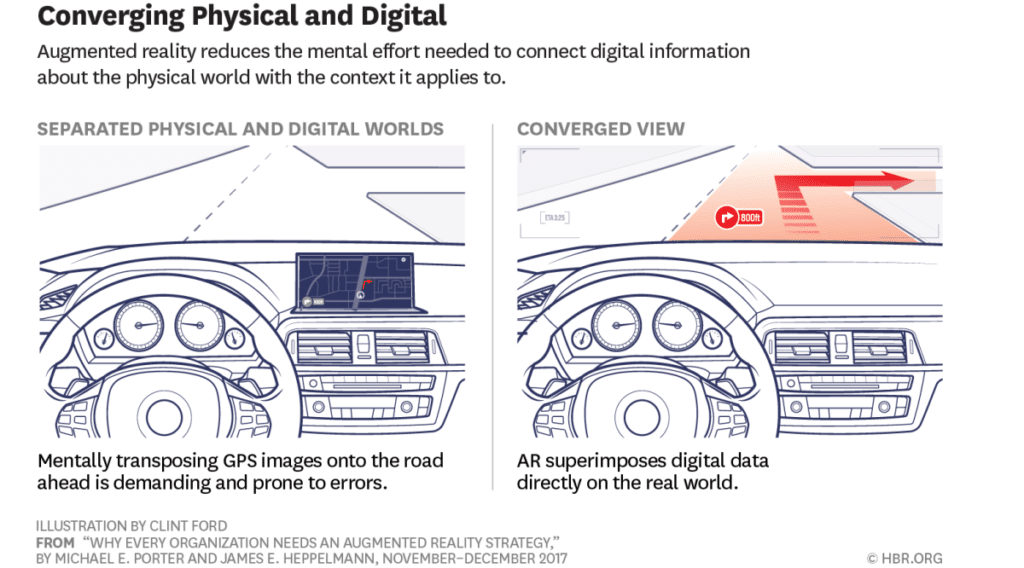

Plus largement, la RA permet un nouveau paradigme de diffusion de l’information qui, selon nous, aura un impact profond sur la manière dont les données sont structurées, gérées et diffusées sur l’internet. Bien que le web ait transformé la manière dont les informations sont collectées, transmises et accessibles, son modèle de stockage et de diffusion des données – des pages sur des écrans plats – présente des limites majeures : Il exige que les gens traduisent mentalement des informations en deux dimensions pour les utiliser dans un monde en trois dimensions. Ce n’est pas toujours facile, comme le savent tous ceux qui ont utilisé un manuel pour réparer une photocopieuse de bureau. En superposant des informations numériques directement sur des objets ou des environnements réels, la RA permet aux gens de traiter le physique et le numérique simultanément, éliminant la nécessité de faire le lien mentalement entre les deux. Cela améliore notre capacité à absorber rapidement et précisément les informations, à prendre des décisions et à exécuter rapidement et efficacement les tâches requises.

Les écrans RA dans les voitures en sont une illustration vivante. Jusqu’à récemment, les conducteurs utilisant la navigation par GPS devaient regarder une carte sur un écran plat, puis trouver comment l’appliquer dans le monde réel. Pour prendre la bonne sortie d’un rond-point très fréquenté, par exemple, le conducteur devait déplacer son regard entre la route et l’écran et relier mentalement l’image de la carte à la bonne sortie. Les affichages tête haute RA superposent les images de navigation directement à ce que le conducteur voit à travers le pare-brise. Cela réduit l’effort mental nécessaire à l’application des informations, évite la distraction et minimise les erreurs de conduite, ce qui permet aux conducteurs de se concentrer sur la route.

La réalité augmentée progresse sur les marchés de consommation, mais son impact émergent sur les performances humaines est encore plus important dans les environnements industriels. Voyez comment Newport News Shipbuilding, qui conçoit et construit les porte-avions de la marine américaine, utilise la RA vers la fin de son processus de fabrication pour inspecter un navire et marquer pour les retirer les structures de construction en acier qui ne font pas partie du porte-avions fini. Par le passé, les ingénieurs devaient constamment comparer le navire réel avec des plans complexes en 2D. Mais avec la RA, ils peuvent désormais voir la conception finale superposée au navire, ce qui réduit le temps d’inspection de 96 %, passant de 36 heures à seulement 90 minutes. Dans l’ensemble, les gains de temps de 25 % ou plus sont typiques des tâches de fabrication utilisant la RA.

Les produits connectés qui se répandent dans nos maisons, nos lieux de travail et nos usines permettent aux utilisateurs de surveiller les opérations et les conditions des produits en temps réel, de contrôler et de personnaliser les opérations des produits à distance, et d’optimiser les performances des produits à l’aide de données en temps réel. Et dans certains cas, l’intelligence et la connectivité permettent à ces derniers d’être totalement autonomes.

La RA amplifie puissamment la valeur créée par ces capacités. Plus précisément, elle améliore la façon dont les utilisateurs visualisent et donc accèdent à toutes les nouvelles données de surveillance, la façon dont ils reçoivent et suivent les instructions et les conseils sur le fonctionnement des produits, et même la façon dont ils interagissent avec les produits eux-mêmes et les contrôlent.

Les applications de RA fournissent une sorte de vision à rayons X, révélant des caractéristiques internes qui seraient difficiles à voir autrement. Chez AccuVein, société spécialisée dans les dispositifs médicaux, par exemple, la technologie de RA convertit la signature thermique des veines d’un patient en une image superposée à la peau, ce qui permet aux cliniciens de localiser plus facilement les veines. Cela améliore considérablement le taux de réussite des prises de sang et autres procédures vasculaires. La RA fait plus que tripler la probabilité de réussir une piqûre d’aiguille du premier coup et réduit de 45 % la nécessité d’une “escalade” (appel à l’aide, par exemple).

Bosch Rexroth, fournisseur mondial d’unités de puissance et de commandes utilisées dans l’industrie manufacturière, utilise une visualisation améliorée par la RA pour démontrer la conception et les capacités de son unité de puissance hydraulique CytroPac intelligente et connectée. L’application de RA permet aux clients de voir des représentations en 3D des options de pompe et de refroidissement internes de l’unité dans de multiples configurations et de voir comment les sous-systèmes s’assemblent.

Une démonstration de salle d’exposition en réalité augmentée développée par Microsoft et Volvo offre une vue aux rayons X du moteur et du châssis d’une voiture.

La RA redéfinit déjà l’instruction, la formation et le coaching. Ces fonctions essentielles, qui améliorent la productivité de la main-d’œuvre, sont par nature coûteuses et laborieuses et donnent souvent des résultats inégaux. Les instructions écrites pour les tâches d’assemblage, par exemple, sont souvent difficiles à suivre et prennent beaucoup de temps. Les vidéos d’instruction standard ne sont pas interactives et ne peuvent pas s’adapter aux besoins d’apprentissage individuels. La formation en personne est coûteuse et exige que les étudiants et les enseignants se réunissent sur un site commun, parfois à plusieurs reprises. Et si l’équipement sur lequel les étudiants sont formés n’est pas disponible, ils peuvent avoir besoin d’une formation supplémentaire pour transférer ce qu’ils ont appris dans un contexte réel.

La RA permet de résoudre ces problèmes en fournissant un guidage visuel en temps réel, sur site, étape par étape, pour des tâches telles que l’assemblage de produits, le fonctionnement de machines et la préparation de commandes en entrepôt. Les représentations schématiques compliquées en 2D d’une procédure dans un manuel, par exemple, deviennent des hologrammes interactifs en 3D qui guident l’utilisateur à travers les processus nécessaires. Peu de choses sont laissées à l’imagination ou à l’interprétation.

Un employé de la société Agco, spécialisée dans les équipements agricoles, consulte les instructions de l’AR pour travailler sur la valve hydraulique d’un tracteur.

Chez Boeing, la formation en RA a eu un impact considérable sur la productivité et la qualité des procédures complexes de fabrication des avions. Dans une étude de Boeing, la RA a été utilisé pour guider les stagiaires à travers les 50 étapes nécessaires à l’assemblage d’une section d’aile d’avion comprenant 30 pièces. Avec l’aide de la RA, les stagiaires ont réalisé le travail en 35 % moins de temps que les stagiaires utilisant les dessins et la documentation traditionnels en 2D. Et le nombre de stagiaires ayant peu ou pas d’expérience qui ont pu effectuer l’opération correctement du premier coup a augmenté de 90 %.

Au fond, la puissance de la réalité augmentée découle de la façon dont les humains traitent l’information. Nous accédons aux informations par chacun de nos cinq sens, mais à des rythmes différents. La vision nous fournit de loin le plus d’informations : On estime que 80 à 90 % des informations que les humains obtiennent sont accessibles par la vision.

Notre capacité à absorber et à traiter les informations est limitée par notre capacité mentale. La pression exercée sur cette capacité est appelée “charge cognitive”. Chaque tâche mentale que nous entreprenons réduit la capacité disponible pour d’autres tâches simultanées.

La charge cognitive dépend de l’effort mental nécessaire pour traiter un type d’information donné. Par exemple, lire des instructions sur un écran d’ordinateur et agir en conséquence crée une charge cognitive plus importante que d’entendre ces mêmes instructions, car les lettres doivent être traduites en mots et les mots interprétés. La charge cognitive dépend également de la “distance cognitive”, c’est-à-dire de l’écart entre la forme sous laquelle l’information est présentée et le contexte dans lequel elle est appliquée. Considérez ce qui se passe lorsqu’une personne consulte un smartphone pour obtenir des indications pendant qu’elle conduit. Le conducteur doit consommer les informations de l’écran, les conserver dans sa mémoire de travail, traduire les instructions dans l’environnement physique qui se trouve devant lui, puis agir en fonction de ces instructions, tout en conduisant le véhicule. Il existe une distance cognitive importante entre les informations numériques sur l’écran et le contexte physique dans lequel les informations sont appliquées. La gestion de cette distance crée une charge cognitive.

La combinaison de la vitesse à laquelle l’information est transmise et absorbée et de la distance cognitive nécessaire à son application est à l’origine de la phrase souvent répétée “Une image vaut mille mots”. Lorsque nous observons le monde physique, nous absorbons presque instantanément une quantité et une variété énormes d’informations. De même, une image ou une photo qui superpose des informations au monde physique, en les plaçant dans leur contexte pour nous, réduit la distance cognitive et minimise la charge cognitive.

Cela explique pourquoi la RA est si puissante. Il n’existe pas de meilleure interface utilisateur graphique que le monde physique qui nous entoure, lorsqu’il est enrichi par une superposition numérique de données et de conseils pertinents à l’endroit et au moment où ils sont nécessaires. La RA élimine la dépendance à l’égard d’informations bidimensionnelles hors contexte et difficiles à traiter sur des pages et des écrans, tout en améliorant considérablement notre capacité à comprendre et à appliquer les informations dans le monde réel.

Traditionnellement, les gens utilisent des commandes physiques telles que des boutons, des molettes et, plus récemment, des écrans tactiles intégrés pour interagir avec les produits. Avec l’essor des produits de consommation connectés, les applications sur les appareils mobiles ont de plus en plus remplacé les commandes physiques et permis aux utilisateurs de faire fonctionner les produits à distance.

La RA porte l’interface utilisateur à un tout autre niveau. Il est possible de superposer un panneau de commande virtuel directement sur le produit et de l’utiliser à l’aide d’un casque de RA, de gestes de la main et de commandes vocales. Bientôt, les utilisateurs portant des lunettes intelligentes pourront simplement regarder ou pointer un produit pour activer une interface utilisateur virtuelle et le faire fonctionner. Un ouvrier portant des lunettes intelligentes, par exemple, pourra parcourir une ligne de machines d’usine, voir leurs paramètres de performance et régler chaque machine sans la toucher physiquement.

La capacité d’interaction de la RA est encore balbutiante dans les produits commerciaux, mais elle est révolutionnaire. URBASEE, une application de catalogue augmenté en réalité augmentée développée par Artefacto, donne un aperçu de la façon dont elle évolue rapidement. URBASEE permet d’ajouter facilement une expérience interactive de RA à n’importe quel produit. Grâce à l’application, les gens peuvent projeter depuis un smartphone ou une tablette un produit dans un environnement réel, le configurer et le visualiser en temps réel.

La réalité virtuelle (RV), cousine bien connue de la RA, est une technologie complémentaire, mais distincte. Alors que la RA superpose des informations numériques sur le monde physique, la RV remplace la réalité physique par un environnement généré par ordinateur. Bien que la RV soit principalement utilisée pour des applications de divertissement, elle peut également reproduire des environnements physiques à des fins de formation. Elle est particulièrement utile lorsque les environnements concernés sont dangereux ou éloignés. Ou, si les machines nécessaires à la formation ne sont pas disponibles, la RV peut immerger les techniciens dans un environnement virtuel en utilisant des hologrammes de l’équipement. Ainsi, lorsque cela est nécessaire, la RV ajoute une quatrième capacité – la simulation – aux capacités de base de la RA, à savoir la visualisation, l’instruction et l’interaction.

La RA sera beaucoup plus largement appliquée dans les entreprises que la RV. Mais dans certaines circonstances, la combinaison de la RA et de la RV permettra aux utilisateurs de transcender la distance (en simulant des lieux éloignés), de transcender le temps (en reproduisant des contextes historiques ou en simulant des situations futures possibles) et de transcender l’échelle (en permettant aux utilisateurs de s’engager dans des environnements qui sont soit trop petits, soit trop grands pour être vécus directement). En outre, le fait de rassembler des personnes dans des environnements virtuels partagés peut améliorer la compréhension, le travail d’équipe, la communication et la prise de décision.

Ford, par exemple, utilise la RV pour créer un atelier virtuel où des ingénieurs géographiquement dispersés peuvent collaborer en temps réel sur des hologrammes de prototypes de véhicules. Les participants peuvent se promener et pénétrer dans ces hologrammes 3D grandeur nature, afin d’affiner des détails de conception tels que la position du volant, l’angle du tableau de bord et l’emplacement des instruments et des commandes, sans avoir à construire un prototype physique coûteux et à réunir tout le monde au même endroit pour l’examiner.

Certaines entreprises vont encore plus loin en combinant des instructions de RA avec des simulations de RV pour former le personnel à réagir à des situations d’urgence telles que des explosions. Cela réduit les coûts et, dans les cas où la formation en environnement réel serait dangereuse, les risques. La multinationale de l’énergie BP superpose des procédures de formation en RA à des simulations en RV qui reproduisent des conditions de forage spécifiques, comme la température, la pression, la topographie et les courants océaniques, et qui instruisent les équipes sur les opérations et les aident à s’entraîner à des réponses d’urgence coordonnées en cas de catastrophe, sans coûts ni risques élevés.

La RA crée de la valeur commerciale de deux manières : d’abord, en s’intégrant aux produits eux-mêmes, puis en améliorant les performances tout au long de la chaîne de valeur – développement de produits, fabrication, marketing, service et de nombreux autres domaines.

Les capacités de la RA s’inscrivent dans le cadre d’une conception de plus en plus axée sur la création d’interfaces utilisateur et d’une ergonomie améliorées. La façon dont les produits transmettent aux utilisateurs des informations importantes sur le fonctionnement et la sécurité est de plus en plus un point de différenciation (voyez comment les applications mobiles ont complété ou remplacé les écrans intégrés dans des produits comme les lecteurs audio Sonos). La RA est prête à améliorer rapidement ces interfaces.

Les affichages tête haute dédiés à la RA, qui n’ont été intégrés que récemment dans les automobiles, sont depuis des années une caractéristique essentielle des produits militaires d’élite, tels que les avions de chasse, et ont également été adoptés dans les avions commerciaux. Ces types d’affichage sont trop chers et trop encombrants pour être intégrés dans la plupart des produits, mais les lunettes intelligentes constituent une interface révolutionnaire qui a de vastes implications pour tous les fabricants. Avec des lunettes intelligentes, un utilisateur peut voir un affichage AR sur n’importe quel produit capable de communiquer avec lui.

Si vous regardez un four de cuisine à travers des lunettes intelligentes, par exemple, vous pouvez voir un affichage virtuel qui indique la température de cuisson, les minutes restantes sur la minuterie et la recette que vous suivez. Si vous vous approchez de votre voiture, un écran de réalité augmentée pourrait vous montrer qu’elle est verrouillée, que le réservoir de carburant est presque plein et que la pression du pneu arrière gauche est faible.

L’interface utilisateur de la RA étant purement logicielle et fournie via le cloud, elle peut être personnalisée et évoluer en permanence. Le coût différentiel de la fourniture d’une telle interface est faible, et les fabricants peuvent également économiser des sommes considérables lorsque les boutons, interrupteurs et cadrans traditionnels sont supprimés. Chaque fabricant de produits doit examiner attentivement l’impact perturbateur que cette interface de nouvelle génération peut avoir sur son offre et son positionnement concurrentiel.

Les effets de la RA sont déjà visibles tout au long de la chaîne de valeur, mais ils sont plus avancés dans certains domaines que dans d’autres. En général, les applications de visualisation et d’instruction/guidage ont maintenant le plus grand impact sur les opérations des entreprises, tandis que la capacité d’interaction est encore émergente et en phase de test pilote.

Bien que les ingénieurs utilisent les capacités de conception assistée par ordinateur (CAO) pour créer des modèles en 3-D depuis 30 ans, ils sont limités à l’interaction avec ces modèles à travers des fenêtres en 2-D sur leurs écrans d’ordinateur, ce qui rend plus difficile la conceptualisation complète des designs. La RA permet de superposer des modèles 3D au monde physique sous forme d’hologrammes, ce qui améliore la capacité des ingénieurs à évaluer et à améliorer les conceptions. Par exemple, un hologramme 3D grandeur nature d’un engin de construction peut être placé sur le sol, et les ingénieurs peuvent marcher autour, regarder en dessous et au-dessus, et même entrer à l’intérieur pour apprécier pleinement les lignes de vue et l’ergonomie de sa conception à l’échelle réelle dans le cadre prévu.

La RA permet également aux ingénieurs de superposer des modèles de CAO sur des prototypes physiques afin de comparer leur adéquation. Volkswagen utilise cette technique – qui rend visuellement évidente toute différence entre le dernier modèle et le prototype – pour vérifier l’alignement lors des examens de conception numérique. Cela améliore la précision du processus d’assurance qualité, dans lequel les ingénieurs devaient auparavant comparer minutieusement les dessins en 2D avec les prototypes, et le rend cinq à dix fois plus rapide.

Nous prévoyons que, dans un avenir proche, les dispositifs de RA tels que les téléphones et les lunettes intelligentes, avec leurs caméras, accéléromètres, GPS et autres capteurs intégrés, contribueront de plus en plus à la conception des produits en montrant quand, où et comment les utilisateurs interagissent réellement avec le produit – combien de fois une certaine séquence de réparation est lancée, par exemple. De cette manière, l’interface de la réalité augmentée deviendra une source importante de données.

Dans le secteur de la fabrication, les processus sont souvent complexes, nécessitant des centaines, voire des milliers d’étapes, et les erreurs sont coûteuses. Comme nous l’avons appris, la RA peut fournir la bonne information au moment où elle est nécessaire aux ouvriers des chaînes de montage, réduisant ainsi les erreurs, améliorant l’efficacité et la productivité.

Dans les usines, la RA peut également capturer les informations provenant des systèmes d’automatisation et de contrôle, des capteurs secondaires et des systèmes de gestion des actifs, et rendre visibles les données de surveillance et de diagnostic importantes concernant chaque machine ou processus. Le fait de voir des informations telles que l’efficacité et les taux de défaillance en contexte aide les techniciens de maintenance à comprendre les problèmes et incite les ouvriers à effectuer une maintenance proactive qui peut éviter des temps d’arrêt coûteux.

Iconics, qui est spécialisée dans les logiciels d’automatisation pour les usines et les bâtiments, a commencé à intégrer la RA dans les interfaces utilisateur de ses produits. En associant les informations pertinentes à l’endroit physique où elles seront le mieux observées et comprises, les interfaces de RA permettent une surveillance plus efficace des machines et des processus.

On estime que les opérations d’entreposage représentent environ 20 % de tous les coûts logistiques, tandis que le prélèvement d’articles dans les rayons représente jusqu’à 65 % des coûts d’entreposage. Dans la plupart des entrepôts, les travailleurs effectuent encore cette tâche en consultant une liste papier des articles à collecter, puis en les recherchant. Cette méthode est lente et source d’erreurs.

Le géant de la logistique DHL et un nombre croissant d’autres entreprises utilisent la RA pour améliorer l’efficacité et la précision du processus de préparation des commandes. Les instructions de RA dirigent les travailleurs vers l’emplacement de chaque produit à prélever, puis leur suggèrent le meilleur itinéraire vers le produit suivant. Chez DHL, cette approche a permis de réduire les erreurs, d’impliquer davantage les travailleurs et de réaliser des gains de productivité de 25 %. L’entreprise déploie actuellement le prélèvement guidé par la RA à l’échelle mondiale et teste comment la RA peut améliorer d’autres types d’opérations d’entrepôt, comme l’optimisation de la position des marchandises et des machines dans les aménagements.

Intel utilise également la RA dans ses entrepôts et a obtenu une réduction de 29 % du temps de préparation des commandes, avec des taux d’erreur proches de zéro. De plus, l’application de la RA permet aux nouveaux employés d’Intel d’atteindre immédiatement des vitesses de préparation des commandes 15 % plus rapides que celles des employés qui n’ont reçu qu’une formation traditionnelle.

La RA redéfinit le concept des salles d’exposition et des démonstrations de produits et transforme l’expérience du client. Lorsque les clients peuvent voir virtuellement l’aspect ou le fonctionnement d’un produit dans un environnement réel avant de l’acheter, ils ont des attentes plus précises, sont plus confiants dans leurs décisions d’achat et sont plus satisfaits du produit. À terme, la RA pourrait même réduire le besoin de magasins et de salles d’exposition en brique et mortier.

Lorsque les produits peuvent être configurés avec différentes caractéristiques et options – ce qui peut les rendre difficiles et coûteux à stocker – la RA est un outil marketing particulièrement précieux. Le distributeur français de stores, pergolas, portails et fenêtres Monsieur Store, par exemple, utilise la RA dans ses catalogues augmentés pour permettre à ses commerciaux et revendeurs de valoriser sa gamme de produits et accélérer le processus de décision de ses clients. Les vendeurs peuvent montrer aux consommateurs l’aspect des produits dans différentes couleurs et dispositions. Les clients peuvent également voir les simulations dans leur contexte : Si vous regardez une maison sur un téléphone ou une tablette, l’application de RA peut y ajouter une pergola. Cette expérience réduit l’incertitude que les clients pourraient ressentir quant à leurs choix et raccourcit le cycle de vente.

Dans le domaine du commerce électronique, les applications de RA permettent aux acheteurs en ligne de télécharger des hologrammes des produits. Wayfair et IKEA proposent tous deux des bibliothèques contenant des milliers d’images de produits en 3D et des applications qui les intègrent dans la vue d’une pièce réelle, ce qui permet aux clients de voir comment les meubles et la décoration se présenteront chez eux. IKEA utilise également son application pour recueillir des données importantes sur les préférences en matière de produits dans différentes régions.

Il s’agit d’une fonction où la RA présente un énorme potentiel pour libérer les capacités de création de valeur des produits connectés. La RA aide les techniciens qui servent les clients sur le terrain de la même manière qu’elle aide les ouvriers dans les usines : en leur montrant les données d’analyse prédictive générées par le produit, en les guidant visuellement dans les réparations en temps réel et en les connectant à des experts à distance qui peuvent les aider à optimiser les procédures. Par exemple, un tableau de bord de RA peut révéler à un technicien sur le terrain qu’une pièce de machine spécifique est susceptible de tomber en panne dans un mois, ce qui lui permet de prévenir un problème pour le client en la remplaçant maintenant.

Chez KPN, un fournisseur européen de services de télécommunications, les ingénieurs de terrain qui effectuent des réparations à distance ou sur site utilisent des lunettes intelligentes de réalité augmentée pour consulter les données de l’historique de service d’un produit, les diagnostics et les tableaux de bord d’informations géolocalisées. Ces affichages de RA les aident à prendre de meilleures décisions sur la manière de résoudre les problèmes, ce qui entraîne une réduction de 11 % des coûts globaux pour les équipes de service, une diminution de 17 % des taux d’erreurs de travail et une meilleure qualité de réparation.

La RA réduit considérablement les erreurs et augmente la productivité dans les usines.

Xerox a utilisé la RA pour mettre en relation les ingénieurs de terrain avec des experts au lieu de fournir des manuels d’entretien et une assistance téléphonique. Le taux de réparation initiale a augmenté de 67 % et l’efficacité des ingénieurs a fait un bond de 20 %. Parallèlement, le temps moyen nécessaire à la résolution des problèmes a diminué de deux heures, ce qui a permis de réduire les besoins en personnel. Aujourd’hui, Xerox utilise la RA pour mettre les experts techniques à distance en contact direct avec les clients. Cela a permis d’augmenter de 76 % le taux de résolution des problèmes techniques par les clients sans aide sur place, réduisant ainsi les frais de déplacement pour Xerox et minimisant les temps d’arrêt pour les clients. Sans surprise, Xerox a vu le taux de satisfaction de ses clients passer à 95 %.

La réalité augmentée offre un large éventail de solutions pour répondre aux anciens et aux nouveaux défis en matière de ressources humaines : recrutement, formation, fidélisation et attractivité des collaborateurs.

La distanciation sociale rendue obligatoire par la pandémie bouleverse la gestion des collaborateurs. Les directions des ressources humaines ont donc été contraintes de repenser leur modèle d’accompagnement et de formation des salariés. Sans la possibilité de dispenser des formations en présentiel, la RA s’est imposée comme une des solutions prioritaires.

Des utilisateurs de la RA, tels que DHL ou Airbus, ont déjà découvert la puissance de la RA, qui permet de dispenser une formation visuelle étape par étape aux travailleurs, à la demande. La RA permet d’adapter l’instruction à l’expérience d’un travailleur particulier ou de refléter la prévalence de certaines erreurs. Par exemple, si une personne commet régulièrement le même type d’erreur, on peut lui demander d’utiliser la RA jusqu’à ce que la qualité de son travail s’améliore. Dans certaines entreprises, la RA a permis de réduire à presque zéro le temps de formation des nouveaux employés pour certains types de travail et d’abaisser les exigences en matière de compétences pour les nouvelles recrues.

La RA aura un impact considérable sur la compétitivité des entreprises. En effet, les produits connectés modifient la structure de presque tous les secteurs d’activité ainsi que la nature de la concurrence au sein de ces secteurs, en repoussant souvent les limites de ces derniers. Ils donnent lieu à de nouveaux choix stratégiques pour les fabricants, qu’il s’agisse de la fonctionnalité à poursuivre et de la manière de gérer les droits et la sécurité des données, ou de l’opportunité d’étendre la gamme de produits d’une entreprise et d’entrer en concurrence dans les systèmes intelligents.

La pénétration croissante de la RA, soulève de nouvelles questions stratégiques. Bien que les réponses reflètent l’activité et les circonstances uniques de chaque entreprise, la RA fera de plus en plus partie intégrante de la stratégie de chaque entreprise.

Voici les questions essentielles auxquelles les entreprises sont confrontées :

1. Quel est l’éventail des opportunités de RA dans l’industrie, et dans quel ordre faut-il les saisir ?

Les entreprises doivent évaluer l’impact potentiel de la RA sur les clients, les capacités des produits et la chaîne de valeur.

2. Comment la RA renforcera-t-elle la différenciation des produits d’une entreprise ?

La RA ouvre de multiples voies de différenciation. Elle peut créer des expériences complémentaires qui étendent les capacités des produits, donnent plus d’informations aux clients et augmentent la fidélité aux produits. Les interfaces de RA qui améliorent la fonctionnalité ou la facilité d’utilisation des produits peuvent être des facteurs de différenciation importants, tout comme celles qui améliorent considérablement le support, le service et le temps de fonctionnement des produits. Et la capacité de la RA à fournir de nouveaux types de retour d’information sur la façon dont les clients utilisent les produits peut aider les entreprises à découvrir d’autres opportunités de différenciation des produits. La bonne voie de différenciation dépendra de la stratégie existante de l’entreprise, de ce que font les concurrents et du rythme des avancées technologiques, notamment en matière de matériel.

3. Où la RA aura-t-elle le plus grand impact sur la réduction des coûts ?

La RA permet de nouvelles efficacités que chaque entreprise doit explorer. Comme nous l’avons noté, elle peut réduire considérablement les coûts de formation, de service, d’assemblage, de conception et d’autres éléments de la chaîne de valeur. Elle peut également réduire considérablement les coûts de fabrication en diminuant le besoin d’interfaces physiques.

Chaque entreprise devra donner la priorité aux efforts de réduction des coûts liés à la RA d’une manière qui soit cohérente avec son positionnement stratégique. Les entreprises proposant des produits sophistiqués devront tirer parti de l’interface supérieure et peu coûteuse de la RA, tandis que de nombreux producteurs de produits de base se concentreront sur l’efficacité opérationnelle tout au long de la chaîne de valeur. Dans les industries de consommation et le commerce de détail, les applications de visualisation liées au marketing sont le point de départ le plus probable. Dans l’industrie manufacturière, les applications d’instruction obtiennent les résultats les plus immédiats en remédiant aux inefficacités de l’ingénierie, de la production et du service. Et la capacité d’interaction de la RA, bien qu’encore émergente, sera importante dans tous les secteurs où les produits sont personnalisés et ont des capacités de contrôle complexes.

4. L’entreprise doit-elle faire de la conception et du déploiement de la RA une de ses principales forces, ou l’externalisation ou les partenariats seront-ils suffisants ?

De nombreuses entreprises s’efforcent de trouver les talents numériques nécessaires au développement de la RA, qui sont rares. Une compétence très demandée est la conception de l’expérience ou de l’interface utilisateur (UX/UI). Il est essentiel de présenter les informations numériques en 3-D de manière à ce qu’elles soient faciles à absorber et à utiliser ; les entreprises veulent éviter de créer une expérience de RA époustouflante mais inutile qui irait à l’encontre de son objectif principal. Pour être efficaces, les expériences de réalité augmentée nécessitent également un contenu approprié, et les personnes qui savent comment le créer et le gérer – une autre compétence nouvelle – sont également cruciales. Les capacités de modélisation numérique et la connaissance de la manière de les appliquer aux applications de RA sont également essentielles.

Au fil du temps, nous nous attendons à ce que les entreprises créent des équipes dédiées à la RA, tout comme elles ont mis en place de telles équipes pour créer et gérer des sites Web dans les années 1990 et 2000. Des équipes dédiées seront nécessaires pour mettre en place l’infrastructure qui permettra à ce nouveau média de s’épanouir et pour développer et maintenir le contenu de la RA. De nombreuses entreprises ont commencé à développer des compétences en RA en interne, mais peu les maîtrisent encore.

La question de savoir s’il faut embaucher et former des employés spécialisés dans la RA ou s’associer à des entreprises spécialisées dans les logiciels et les services reste ouverte pour beaucoup. Certaines entreprises n’ont pas d’autre choix que de considérer les compétences en RA comme un actif stratégique et d’investir dans leur acquisition et leur développement, étant donné l’impact potentiellement important de la RA sur la concurrence dans leur secteur. Toutefois, si la RA est importante mais pas essentielle à l’avantage concurrentiel, les entreprises peuvent s’associer à des sociétés spécialisées dans les logiciels et les services pour tirer parti des talents et de la technologie externes.

Les défis, le temps et les coûts nécessaires à la mise en place de l’ensemble des technologies de la RA que nous avons décrites sont importants, et la spécialisation émerge toujours dans chaque composant. Aux premiers stades de la RA, le nombre de fournisseurs de technologies et de services était limité et les entreprises ont développé des capacités internes. Cependant, les meilleurs vendeurs de RA avec des solutions clés en main commencent à apparaître et il sera de plus en plus difficile pour les efforts internes de les suivre.

5. Comment la RA va-t-elle changer la communication avec les parties prenantes ?

La RA complète les approches de communication imprimées et numériques 2-D existantes et, dans certains cas, peut les remplacer complètement. Cependant, nous considérons la RA comme bien plus qu’un simple canal de communication supplémentaire. Il s’agit d’un moyen fondamentalement nouveau d’entrer en contact avec les gens. Il suffit de penser à la manière originale dont elle aide les gens à absorber et à agir sur les informations et les instructions. Le web, qui était au départ un moyen de partager des rapports techniques, a fini par transformer les affaires, l’éducation et les interactions sociales. Nous pensons que la RA fera la même chose pour la communication, en la modifiant bien au-delà de ce que nous pouvons imaginer aujourd’hui. Les entreprises devront faire preuve de créativité dans l’utilisation de ce canal naissant.

Les applications de RA font déjà l’objet de projets pilotes et sont déployées dans des produits et sur l’ensemble de la chaîne de valeur, et leur nombre et leur ampleur ne feront que croître.

Chaque entreprise a besoin d’une feuille de route de mise en œuvre qui indique comment l’organisation va commencer à profiter des avantages de la RA dans ses activités tout en développant les capacités nécessaires pour étendre son utilisation. Lorsqu’elles déterminent la séquence et le rythme d’adoption, les entreprises doivent tenir compte à la fois des défis techniques et des compétences organisationnelles en jeu, qui varient d’un contexte à l’autre. Plus précisément, les organisations doivent répondre à cinq questions clés :

1. Quelles capacités de développement seront nécessaires ?

Certaines expériences de RA sont plus complexes que d’autres. Les expériences qui permettent aux gens de visualiser des produits dans différentes configurations ou réglages – comme celles créées par IKEA, Wayfair et AZEK – sont un point de départ relativement facile pour les entreprises. Il suffit d’encourager les consommateurs à télécharger et à lancer des applications de RA, et un appareil mobile suffit pour les utiliser. Les applications d’instruction, comme celles que Boeing et GE utilisent dans la fabrication, sont plus difficiles à construire et à utiliser. Elles requièrent la capacité de développer et de maintenir un contenu numérique dynamique en 3D et bénéficient souvent grandement de l’utilisation d’écrans montés sur la tête ou de lunettes intelligentes, qui en sont encore aux premiers stades de développement.

Les applications qui produisent des expériences interactives, qui créent une valeur importante pour les consommateurs et les entreprises, sont les plus difficiles à développer. Elles impliquent également des technologies moins matures, comme la reconnaissance vocale ou gestuelle, et la nécessité de s’intégrer aux logiciels qui contrôlent les produits connectés. La plupart des entreprises commenceront par des visualisations statiques de modèles 3D, mais elles devraient se doter de la capacité de passer rapidement à des expériences pédagogiques dynamiques ayant un impact stratégique plus important.

2. Comment les organisations doivent-elles créer du contenu numérique ?

Toute expérience de RA, de la moins sophistiquée à la plus sophistiquée, nécessite du contenu. Dans certains cas, il est possible de réutiliser du contenu numérique existant, comme des conceptions de produits. Toutefois, au fil du temps, des expériences contextuelles dynamiques plus complexes doivent être créées de toutes pièces, ce qui nécessite une expertise spécialisée.

Les applications simples, telles qu’un catalogue de meubles amélioré par la RA, peuvent ne nécessiter que des représentations de base des produits. En revanche, les applications d’instruction commerciale plus sophistiquées, telles que celles utilisées pour la réparation des machines, nécessitent des représentations numériques précises et très détaillées des produits. Les entreprises peuvent créer ces représentations en adaptant les modèles de CAO utilisés pour le développement des produits ou en utilisant des techniques de numérisation telles que le balayage en 3D. Les expériences de RA les plus sophistiquées doivent également exploiter les flux de données en temps réel des systèmes d’entreprise, des produits connectés ou des sources de données externes et les intégrer au contenu. Pour se préparer à élargir le portefeuille de la RA, les entreprises doivent faire l’inventaire des actifs numériques 3D existants dans la CAO et ailleurs et investir dans des capacités de modélisation numérique.

3. Comment les applications de RA reconnaîtront-elles l’environnement physique ?

Pour superposer avec précision des informations numériques sur le monde physique, les technologies de RA doivent reconnaître ce qu’elles regardent. L’approche la plus simple consiste à déterminer l’emplacement du dispositif de RA à l’aide, par exemple, du GPS et à afficher les informations pertinentes pour cet emplacement sans l’ancrer à un objet spécifique. C’est ce qu’on appelle une expérience de RA “non enregistrée”. Les écrans de navigation tête haute des véhicules fonctionnent généralement de cette manière.

Les expériences “enregistrées” de plus grande valeur ancrent les informations à des objets spécifiques. Elles peuvent le faire par le biais de marqueurs, tels que des codes-barres, des logos ou des étiquettes, qui sont placés sur les objets et scannés par l’utilisateur avec un dispositif de RA. Une approche plus puissante, cependant, utilise une technologie qui reconnaît les objets en comparant leur forme à un catalogue de modèles en 3D. Cela permet à un technicien de maintenance, par exemple, de reconnaître instantanément et d’interagir avec n’importe quel type d’équipement dont il est responsable de la maintenance, et ce, sous n’importe quel angle. Si les marqueurs constituent un bon point de départ, les technologies de reconnaissance de forme progressent rapidement et les entreprises devront être en mesure de les utiliser pour exploiter les nombreuses applications de RA à forte valeur ajoutée.

4. Quel matériel de RA est nécessaire ?

Les expériences de RA destinées à un large public ont généralement été conçues pour les smartphones, en tirant parti de leur simplicité et de leur omniprésence. Pour des expériences plus sophistiquées, les entreprises utilisent des tablettes, qui offrent des écrans plus grands, de meilleurs graphismes et une plus grande puissance de traitement. La pénétration des tablettes étant plus faible, les entreprises les fournissent souvent aux utilisateurs. Pour certaines applications à forte valeur ajoutée, notamment dans les avions et les automobiles, les fabricants intègrent des affichages tête haute dédiés à la RA dans leurs produits, une approche coûteuse.

À terme, cependant, la plupart des applications de RA pour les services, la fabrication et même les interfaces de produits nécessiteront des affichages tête haute qui libèrent les mains des utilisateurs. Cette technologie est actuellement à la fois immature et coûteuse, mais nous pensons que des lunettes intelligentes abordables deviendront largement disponibles dans les prochaines années et joueront un rôle majeur dans la libération de toute la puissance de la RA. Microsoft, Google et Apple proposent désormais des technologies de RA optimisées pour leurs propres appareils. Cependant, la plupart des organisations devraient adopter une approche multiplateforme permettant de déployer des expériences de RA sur plusieurs marques de téléphones et de tablettes et s’assurer qu’elles sont prêtes pour les lunettes intelligentes lorsqu’elles arriveront. (Voir “La bataille des lunettes intelligentes”).

5. Devriez-vous utiliser un modèle de développement de logiciels ou un modèle d’édition de contenu ?

De nombreuses premières expériences de RA ont été proposées par le biais d’applications logicielles autonomes qui sont téléchargées, avec leur contenu numérique, sur un téléphone ou une tablette. Cette approche crée des expériences fiables et à hautes résolutions et permet aux organisations de créer des applications qui ne nécessitent pas de connexion à Internet. Le problème de ce modèle est que toute modification de l’expérience de RA nécessite que les développeurs de logiciels réécrivent l’application, ce qui peut créer des goulots d’étranglement coûteux.

Une alternative émergente utilise un logiciel commercial d’édition de RA pour créer du contenu RA et l’héberger dans le nuage. L’expérience de réalité augmentée peut ensuite être téléchargée à la demande à l’aide d’une application polyvalente fonctionnant sur un dispositif de réalité augmentée. Comme le contenu d’un site web, le contenu de la RA peut être mis à jour ou complété sans modifier le logiciel lui-même, ce qui constitue un avantage important lorsque de grandes quantités d’informations et des modifications fréquentes du contenu sont en jeu. Le modèle de publication de contenu deviendra courant à mesure que de plus en plus de machines et de produits comprendront une interaction et un contrôle de la RA en temps réel. Une capacité de publication de contenu est essentielle pour étendre la RA à l’ensemble de l’entreprise.

La révolution numérique, avec ses produits connectés et son explosion de données, libère la productivité et dégage de la valeur dans toute l’économie. De plus en plus, la contrainte n’est pas le manque de données et de connaissances, mais la manière de les assimiler et d’agir sur elles – en d’autres termes, l’interface avec les humains. La RA apparaît comme une solution de premier plan pour relever ce défi. Dans le même temps, l’évolution rapide de l’apprentissage automatique et de l’automatisation soulève de sérieuses inquiétudes quant aux opportunités humaines. Y aura-t-il suffisamment d’emplois pour tout le monde, en particulier pour les personnes sans formation ni connaissances avancées ? Dans un monde d’intelligence artificielle et de robots, les humains deviendront-ils obsolètes ?

Il est facile de conclure que les nouvelles technologies réduisent les opportunités humaines. Pourtant, les nouvelles inventions remplacent le travail humain depuis des siècles, et elles ont entraîné une croissance de l’emploi, et non un déclin. La technologie a considérablement augmenté notre productivité et notre niveau de vie. Elle a donné naissance à de nouveaux types d’offres qui répondent à de nouveaux besoins et requièrent de nouveaux types de travailleurs. Bon nombre des emplois d’aujourd’hui concernent des produits et des services qui n’existaient même pas il y a cent ans. Une leçon de l’histoire est que la révolution numérique actuelle va générer de nouvelles vagues d’innovation et de nouveaux types de travail que nous ne pouvons pas encore imaginer.

Le rôle de l’homme dans cet avenir est mal compris. L’être humain possède des atouts uniques que les machines et les algorithmes ne reproduiront pas de sitôt. Nous possédons des capacités motrices sophistiquées – bien au-delà de ce dont les robots sont capables aujourd’hui – qui nous permettent d’effectuer les manipulations subtiles nécessaires, par exemple, pour remplacer une pièce de machine ou câbler une turbine. Même les tâches relativement peu qualifiées, telles que la prise de sang, la taille d’un jardin ou la réparation d’un pneu crevé, nécessitent une dextérité humaine et défient l’automatisation. La cognition humaine s’adapte instantanément aux situations nouvelles ; les gens adaptent facilement leur façon d’interpréter les informations, de résoudre les problèmes, d’exercer leur jugement et d’agir en fonction des circonstances. L’être humain possède une flexibilité, une imagination, une intuition et une capacité créative qui, dans un avenir prévisible, sont hors de portée de toute machine.

Bien que les progrès de l’intelligence artificielle et de la robotique soient impressionnants, nous pensons que la combinaison des capacités des machines avec les forces distinctives des humains conduira à une productivité et à une création de valeur bien supérieures à celles que l’une ou l’autre pourrait générer seule. Pour saisir cette opportunité, il faut une interface humaine puissante qui comble le fossé entre le monde numérique et le monde physique. Nous considérons la RA comme une innovation historique qui offre cette possibilité. Elle aide les humains à améliorer leurs propres capacités en tirant pleinement parti des nouvelles connaissances numériques et des capacités des machines. Elle va profondément modifier la formation et le développement des compétences, en permettant aux gens d’effectuer des travaux sophistiqués sans avoir recours à un enseignement conventionnel long et coûteux – un modèle inaccessible pour beaucoup aujourd’hui. La RA permet donc aux gens de mieux exploiter la révolution numérique et tout ce qu’elle a à offrir.