Produire une grande quantité de produits avec la meilleure rentabilité possible, c’est bien l’objectif de tout procédé industriel. Qu’il s’agisse d’automobile, de formulation chimique ou de machines industrielles, l’optimisation des délais et des budgets est une problématique inhérente au secteur de l’industrie.

Aujourd’hui, des technologies innovantes comme la réalité virtuelle et la réalité augmentée sont de plus en plus appréciées et permettent l’optimisation des process industriels. Bonne nouvelle : les outils issus de ces technologies de plus en plus accessibles, par exemple grâce à la démocratisation des casques de réalité virtuelle. Les spécialistes prévoient d’ailleurs la vente de 100 millions d’unités de casques VR en 2021 (source : Cabinet IDC).

Transport, aéronautique, agroalimentaire (IAA), énergie… dans tous ces secteurs, la réalité augmentée et la réalité virtuelle trouvent des usages concrets en matière de procédés industriels. Nombreux sont les avantages.

On peut citer par exemple :

• une meilleure compréhension des procédés industriels pour toutes les parties prenantes

• l’amélioration de l’ergonomie des postes

• l’efficacité des outils d’aide à la vente, à la décision

• la facilité de modélisation

• le gain en temps et en productivité d’un process industriel

• la rentabilité accrue

La réalité augmentée et la réalité virtuelle servent toutes les étapes des procédés industriels

La réalité augmentée et la réalité virtuelle permettent d’optimiser tout le procédé industriel, de la conception à la mise en marché du produit fini :

#1 Conception et fabrication de machines industrielles ou d’unités industrielles

Les maquettes 3D sont d’excellents outils de prévisualisation. Elles permettent de s’assurer de toutes les vérifications nécessaires avant de basculer dans la construction physique définitive. Grâce à elles, l’industriel peut non seulement vérifier le bon assemblage des pièces, détecter les erreurs dans la création d’un prototype, avoir un aperçu fiable du produit industriel fini ainsi que du choix des options. Ce sont aussi de formidables outils pour le travail collaboratif. L’usage de ces outils 3D en industrie facilite, en effet, l’assignation par tâche et le découpage du travail.

La réalité virtuelle peut servir, par exemple, pour la mise en service virtuelle d’une machine. Ainsi, pendant que la machine réelle se fabrique en atelier, les ingénieurs en construisent la version virtuelle en 3D afin de lancer des simulations. Un bon moyen de tester et d’éviter un grand nombre d’erreurs. Résultat : l’optimisation de l’efficacité et de la rentabilité.

Par ailleurs, la réalité augmentée est utilisée pour enrichir l’espace réel. Grâce à l’interactivité qu’elle offre, cette technologie est parfaite pour simuler des process complexes. L’application en réalité augmentée est un excellent outil d’aide à la prise de décision lorsque l’on cherche à essayer plusieurs solutions à une problématique technique. Il est alors possible de décliner différents scénarios et de tester toutes les options.

#2 Simulation augmentée et virtuelle

Autre exemple d’application de la technologie 3D en industrie : la simulation virtuelle et augmentée. Le bénéfice ? Grâce aux calculs et à la modélisation adaptés, la simulation 3D permet de valider la faisabilité industrielle d’un projet avant de développer des prototypes. Comment ? En simulant l’intégrité physique et les caractéristiques fonctionnelles d’un composant qui n’existe pas encore, et en le propulsant dans le réel pour vérifier que l’objet est bien conçu.

Exemple : spécialiste de la modernisation des outils de production, l’entreprise Keonys crée des solutions de gestion du cycle de vie des produits (PLM – Product Lifecycle Management) et 3D. Elle a ont alors choisi d’investir dans la technologie de réalité augmentée, plus précisément dans de la « simulation augmentée ». Ces applications sont d’une grande aide pour éviter tout raté lors du process industriel. Elles permettent, par exemple, de valider le fonctionnement d’un moteur alors que certaines pièces ne sont encore que des prototypes.

« Nous travaillons sur des technologies à base de réalité aumentée pour effectuer un contrôle prédictif des défauts industriels. » explique Jacques Bacry, DG de Keonys.

#3 Maintenance industrielle 3D

Effectuer une opération de maintenance en milieu hostile, c’est-à-dire dans une situation présentant des risques élevés pour l’homme ? C’est ce que permet sans danger la maintenance industrielle en 3D, à l’aide, par exemple, du pilotage d’opérations via une télécommande.

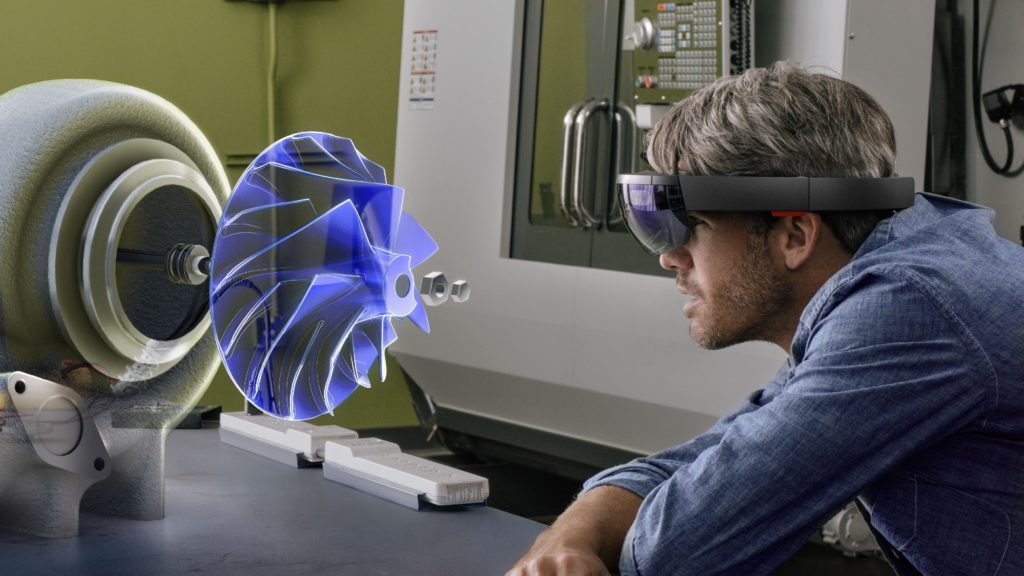

La réalité mixte est une technologie de visualisation de contenu en réalité augmentée par le biais d’un casque. Celle-ci permet d’aller plus loin dans la maintenance assistée. Imaginez le technicien devant la machine. Celui-ci est guidé dans ses opérations par les informations qui apparaissent en Réalité Mixte dans le casque Hololens. Un vrai plus pour gagner en sécurité et en efficacité.

#4 Formation et assistance au fonctionnement pendant l’opération industrielle

La réalité augmentée offre de nombreuses possibilités de formation des équipes industrielles. Que ce soit pour le montage ou la maintenance, ces applications permettent non seulement de former en amont mais aussi d’assister les opérateurs pendant leur travail.

#5 Marketing industriel

Etudes d’implantation, visualisation du projet in situ, présentation d’un procédé ou d’un projet industriel à un organisme externe, visite virtuelle d’usine… la réalité virtuelle ou la réalité augmentée en industrie a aussi bon nombre d’utilités marketing. Les industriels peuvent ainsi montrer leurs produits depuis une application sur mesure, via un catalogue augmenté industriel. Les bénéfices sont nombreux ! Cela valorise les produits, aide les clients à se projeter, donne une image innovante de la marque et surtout, augmente les ventes. Savez-vous qu’il est même désormais possible d’essayer des voitures à distance ?

Exemples de matériel à utiliser en réalité augmentée ou virtuelle selon les usages

Vous vous projetez dans l’usage de la réalité augmentée ou virtuelle, et voulez savoir quels « hardware » sont faits pour vous et vos collaborateurs ? Voici quelques exemples :

● Lunettes

● Ordinateur portable

● Caméra

● Murs d’images

● Écran TV

● Casque VR

● Casque de réalité mixte

Fabrication, simulation, maintenance, formation, marketing industriel… Réalité augmentée et réalité virtuelle permettent d’optimiser à la fois la conception du produit industriel, d’un procédé industriel existant ou d’une installation industrielle. Aujourd’hui, on peut vraiment dire que l’usine virtuelle devient une réalité dans tous les secteurs industriels !

Vous souhaitez en savoir plus sur les applications 3D pour l’industrie ? Téléchargez notre guide !